BMW X5: Removing And Installing/Replacing Oil Pump (N52K)

Necessary preliminary tasks:

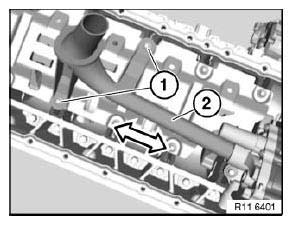

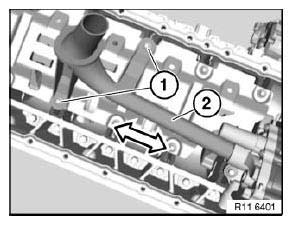

Release screws (1).

Tightening torque: 11 41 1AZ.

Installation:

Replace aluminium screws.

Remove intake pipe (2) in direction of arrow.

Installation:

Replace sealing ring.

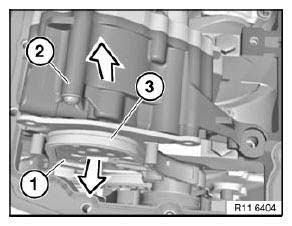

NOTE: To release bolt (1), insert a 6 mm drill bit between sprocket

wheel and oil pump

housing.

Release bolt (1).

Tightening torque: 11 41 6AZ.

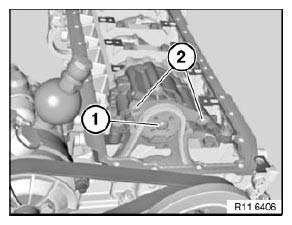

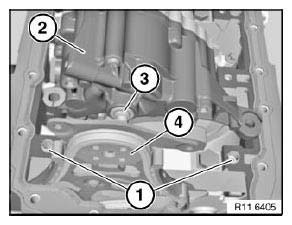

Release screws (2).

Tightening torque: 11 41 5AZ.

Installation:

Replace aluminium screws.

Fig. 246: Bolt And Screw

IMPORTANT: Observe different screw lengths.

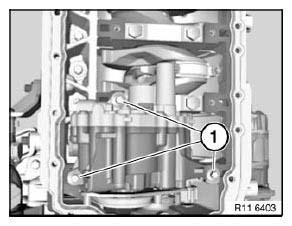

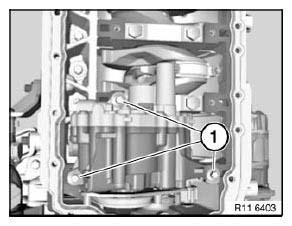

Release screws (1).

Tightening torque: 11 41 2AZ.

Tightening torque: 11 41 3AZ.

Installation:

Replace aluminium screws.

Fig. 247: Screws

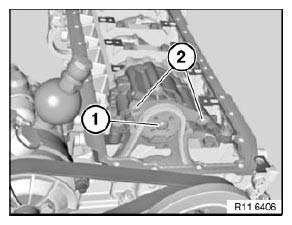

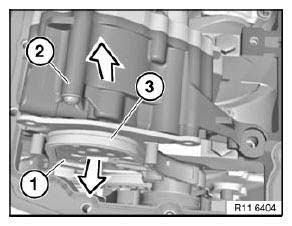

Detach sprocket wheel (1) in direction of arrow.

NOTE: Chain tensioner presses timing chain (3) upwards.

Do not remove sprocket wheel (1).

Remove oil pump (2) in direction of arrow.

Fig. 248: Removing Sprocket Wheel

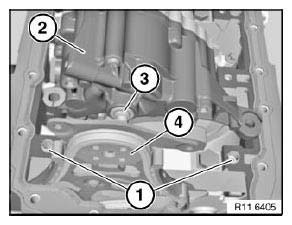

Installation:

Check spacers (1) for secure seating and damage; replace if necessary.

Align twin surface (3) on oil pump (2) to sprocket wheel (4).

Install oil pump (2).

Fig. 249: Spacers, Oil Pump And Sprocket Wheel

Assemble engine.

READ NEXT:

Special tools required:

00 9 140

11 0 290

11 0 300

11 4 120

11 4 280

11 4 360

11 4 362

11 4 440

11 5 200

11 9 280

IMPORTANT: Aluminium-magnesium materials.

No steel screws/bolts may be us

REMOVING AND INSTALLING/REPLACING WATER PUMP (N52K)

WARNING: Danger of scalding!

Only perform this work after engine has cooled down.

Recycling:

Catch and dispose of drained coolant in a suitable cont

REMOVING AND INSTALLING/REPLACING COOLANT THERMOSTAT (N52K)

WARNING: Danger of scalding!

Only perform this work after engine has cooled down.

Recycling

Catch and dispose of drained coolant in a suitab

SEE MORE:

Principle

In the valet parking mode, the Control Display is

disabled. The operation via iDrive is no longer

possible.

E.g., this mode can be used when the vehicle is

handed over for valet parking.

General information

In the valet parking mode, it is not possible to

change vehicle settings via iDriv

OVERVIEW OF MICROSWITCHES

LOCK microswitches, inner, on seat frame on left and right.

FOLD microswitch on backrest frame, outer.

CF microswitch on seat frame, outer.

OVERVIEW OF TRIMS, REAR SEAT

Seatbelt outlet trim.

Trim, CF release unit.

Trim, fold, inner.

Trim, seat screw fastening