BMW X5: Valves With Springs

REMOVING AND INSTALLING/REPLACING ALL VALVES (N52K)

Special tools required:

- 11 4 480

Necessary preliminary tasks:

- Remove cylinder head

- Remove intermediate lever

- Remove eccentric shaft

- Remove inlet camshaft

- Remove exhaust camshaft

- Remove cam followers

- Remove valve springs

- Remove valve stem seals

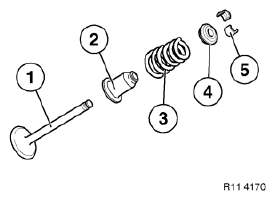

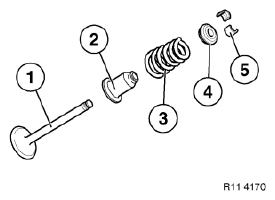

- Valve

- Valve stem seal with lower spring plate

- Valve spring

- Upper spring plate

- Valve tapers

If the valves are to be reused, they must be placed in neat order in special tool 11 4 480.

Fig. 209: Upper Spring Plate, Valve Tapers And Spring

Assemble engine.

Check function of DME; if necessary, readjust uniform mixture distribution.

REPLACING ALL VALVE STEM SEALS (N52K)

Special tools required:

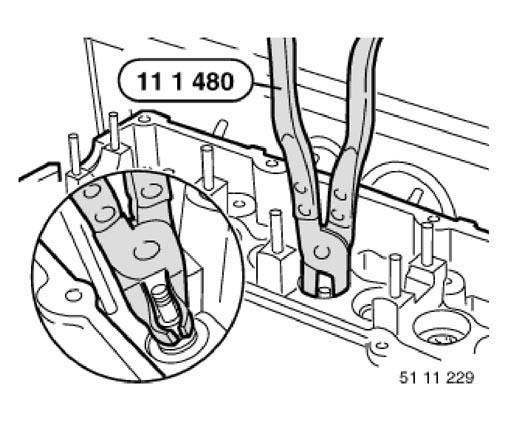

- 11 1 480

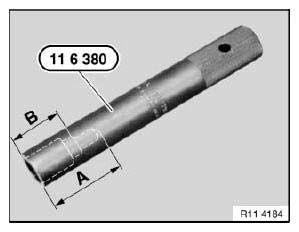

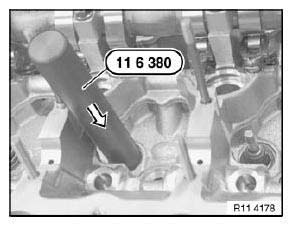

- 11 6 380

Necessary preliminary tasks:

- Remove cylinder head

- Remove intermediate lever

- Remove eccentric shaft

- Remove inlet camshaft

- Remove exhaust camshaft

- Remove cam followers

Firmly press special tool 11 1 480 onto old valve stem seals.

Detach valve stem seal from valve stem by turning and simultaneously pulling special tool 11 1 480.

Installation:

Insert all valves.

Fig. 210: Special Tool (11 1 480)

NOTE: For use on the N52K engine, special tool 11 6 380 must be remachined according to the picture with a 10 mm dia. drill bit to a depth of B = approx. 23 mm.

This modification has already been taken into account for reordering.

Fig. 211: Special Tool (11 6 380) With Dimensions

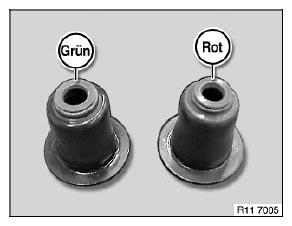

IMPORTANT: Different diameters at valve stem.

All valve stem seals are color-coded.

For 5 mm dia. valves, the valve stem seal is marked red or brown.

For 6 mm dia. valves, the valve stem seal is marked green or light green.

Fig. 212: Valve Stem Seals Color-Coded, Green(Grun), and Red(Rot)

Installation:

Fit the mounting sleeves (plastic sleeves) contained in the delivery specification on the valve stem end.

Lubricate mounting sleeve.

Press on valve stem seal by hand with special tool 11 6 380 as far as it will go.

Fig. 213: Special Tool (11 6 380)

Assemble engine.

REPLACING ALL VALVE SPRINGS (N52K)

Special tools required:

- 11 0 346

- 11 4 480

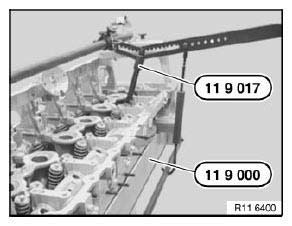

- 11 9 000

- 11 9 017

Necessary preliminary tasks:

- Remove cylinder head

- Remove exhaust camshaft

- Remove intermediate lever

- Remove inlet camshaft

- Remove cam followers

Place cylinder head on special tool 11 9 000.

Press down inlet valves with special tool 11 9 017.

Press down exhaust valves with special tool 11 0 346.

Fig. 214: Special Tool (11 9 017) And (11 9 000)

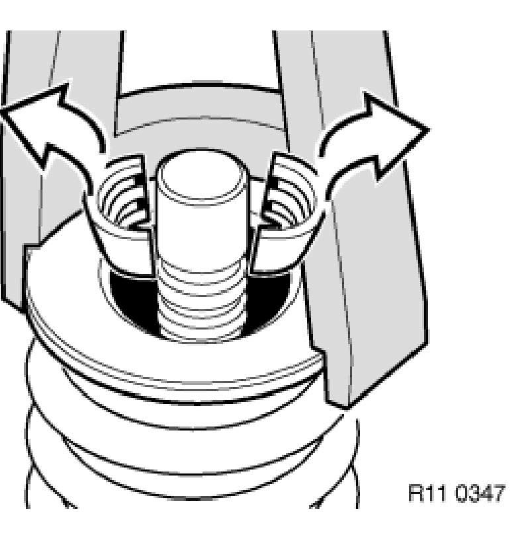

Remove valve cotters with a magnet.

Remove valve spring with spring plates.

If the individual components are to be reused, they must be placed in neat order in special tool 11 4 480.

Fig. 215: Removing Valve Cotters With Magnet

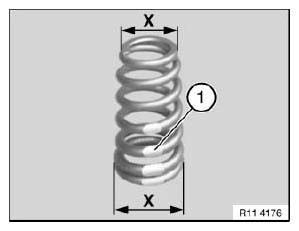

IMPORTANT: Incorrect installation possible.

Incorrect installation will result in valve spring breakage.

Risk of mixing up the valve springs for the inlet and exhaust valves.

The valve spring is color-coded (1) at the lower end.

Install the valve spring so that the larger diameter points to the lower spring plate.

Fig. 216: Valve Spring Color-Coded

Arrangement:

- Valve

- Valve stem seal with lower spring plate

- Valve spring

- Upper spring plate

- Valve tapers

Fig. 217: Upper Spring Plate, Valve Tapers And Spring

Assemble engine.

Check function of DME; if necessary, readjust uniform mixture distribution.