BMW X5: Removing And Installing/Replacing Eccentric Shaft (N52K)

Special tools required:

- 11 4 481

Necessary preliminary tasks:

- Remove cylinder head cover

- Remove intermediate lever

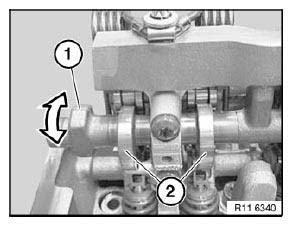

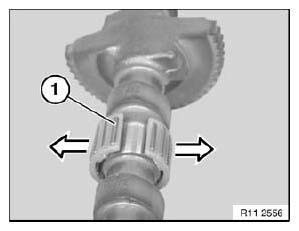

If necessary, move eccentric shaft (1) on twin surface to minimum lift (2).

Fig. 218: Eccentric Shaft

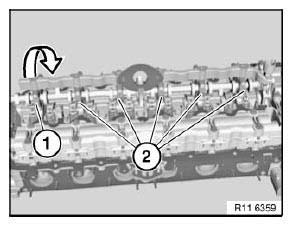

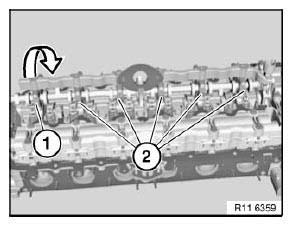

NOTE: All bearing caps (1 and 2) of eccentric shaft are marked with numbers from 1 to 6 (1 for 1st cylinder to 6 for 6th cylinder).

Bearing cap 6 (1) is provided with a stop.

Release screws on bearing cap 6 (1).

Release screws on bearing caps 1 to 5 (2).

Set all bearing caps down in special tool 11 4 481 in a tidy and orderly fashion.

Remove eccentric shaft with gentle tilting and turning movements.

Fig. 219: Bearing Caps

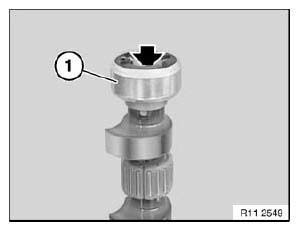

IMPORTANT: Screw is not magnetic and must be secured against falling down.

Release screw.

Remove magnet wheel (1).

Fig. 220: Magnet Wheel

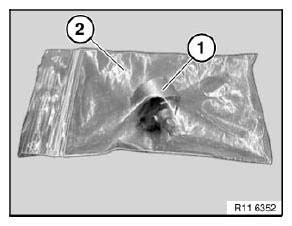

IMPORTANT: Magnet wheel (1) is highly magnetic and must be protected against metal filings/borings.

After removing, place magnet wheel (1) in a plastic bag (2) with a seal.

Fig. 221: Magnet Wheel And Plastic Bag

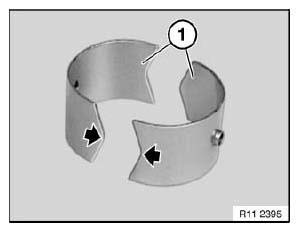

IMPORTANT: Needle bearing (1) can break very easily.

Carefully pull needle bearing (1) apart at point of separation.

Remove all needle bearings (1) from eccentric shaft.

Fig. 222: Removing Needle Bearings From Eccentric Shaft

Install bearing shells (1) as pictured.

NOTE: Always replace bearing shells (1) and needle bearings together.

Fig. 223: Bearing Shells

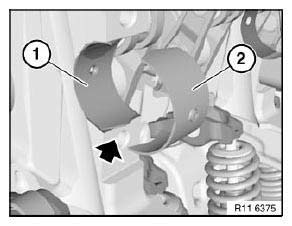

Install bearing shell (1) with tip facing down (see arrow) in cylinder head.

Install bearing shell (2) with tip facing up in bearing cap.

Fig. 224: Bearing Shells

NOTE: All bearing caps (1 and 2) of eccentric shaft are marked with numbers from 1 to 6 (1 for 1st cylinder to 6 for 6th cylinder).

Bearing cap 6 (1) is provided with a stop.

Insert eccentric shaft.

Adjust eccentric shaft on dihedron to minimum stroke.

Fit all bearing caps (1 and 2).

Insert all screws.

Tightening torque: 11 12 7AZ.

Fig. 225: Bearing Caps

Assemble engine.