BMW X5: Removing And Installing Or Replacing Muffler/Silencer

WARNING: Scalding hazard! Work on independent heating may only be carried out when it has cooled down.

Necessary preliminary tasks:

- Remove left underbody panelling.

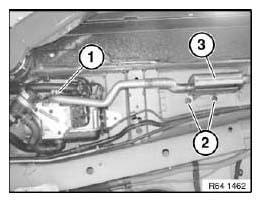

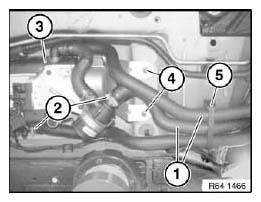

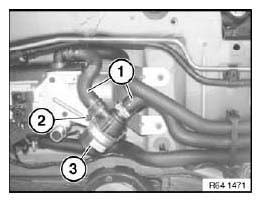

Slacken clamp (1).

Release screws (2) and remove muffler (3).

Tightening torque.

Fig. 45: Identifying Muffler/Silencer And Slacken Clamp

REMOVING AND INSTALLING/REPLACING INTAKE MUFFLER FOR INDEPENDENT/AUXILIARY HEATER

WARNING: Scalding hazard! Work on independent heating may only be carried out when it has cooled down.

Necessary preliminary tasks:

- Remove front wheel arch cover.

- Remove left underbody panelling.

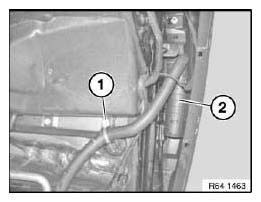

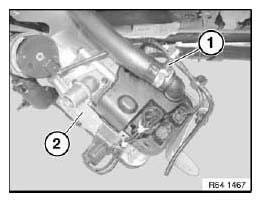

Release screw (1) and unclip intake muffler (2).

Installation:

Retaining clip on intake muffler must not be damaged!

Fig. 46: Identifying Clip On Intake Muffler

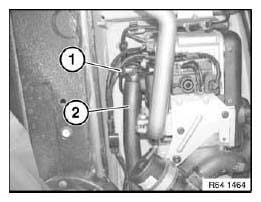

Release hose clamp (1), disconnect air intake hose (2) and feed out.

Fig. 47: Identifying Hose Clamp And Air Intake Hose

REMOVING AND INSTALLING/REPLACING COMPLETE INDEPENDENT HEATER WITH BRACKET

Special tools required:

- 13 3 010

WARNING: Scalding hazard! Work on independent heating may only be carried out when it has cooled down.

Recycling

Fuel escapes when fuel lines are detached. Have a suitable collecting container ready.

Catch and dispose of escaping fuel.

Observe country-specific waste-disposal regulations.

Necessary preliminary tasks:

- Remove left underbody panelling.

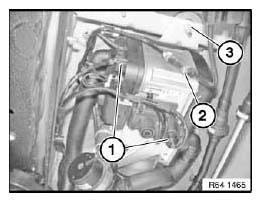

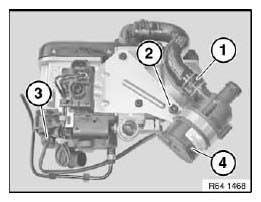

Disconnect plug connection (1).

Release hose clamp (2) and detach fuel line.

Release screw (3).

Tightening torque.

Fig. 48: Identifying Plug Connection And Hose Clamp

IMPORTANT: Secure heater (3) against falling out.

Disconnect coolant hoses (1) with special tool 13 3 010.

Release hose clamps (2) and detach coolant hoses (1).

Release nuts (4) and unclip associated hoses from holder (5).

Remove heater (3) and set down on a suitable surface.

Fig. 49: Identifying Coolant Hoses, Hose Clamps And Heater

Release hose clamp (1) and remove complete heater (2) with bracket.

Fig. 50: Identifying Hose Clamp And Complete Heater

Replacement:

Modify muffler.

Release hose clamp (1) and detach coolant hose.

Release bolt (2).

Tightening torque.

Disconnect plug connection (3) and remove auxiliary water pump (4).

Installation:

Check coolant hoses for damage and replace if necessary.

Fig. 51: Identifying Plug Connection And Auxiliary Water Pump With Bolts

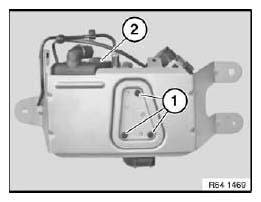

Release screws (1) and remove heater from bracket (2).

Tightening torque.

Fig. 52: Identifying Heater Bracket With Screws

After installation:

- Vent cooling system.

REPLACING AUXILIARY WATER PUMP FOR INDEPENDENT/AUXILIARY HEATER

WARNING: Scalding hazard! Work on the cooling system may only be carried out when it has cooled down.

Recycling

Coolant emerges when coolant lines are detached. Have a suitable collecting container ready.

Catch and dispose of emerging coolant.

Observe country-specific waste-disposal regulations.

Necessary preliminary tasks:

- Remove left floor assembly cover.

NOTE: Disconnect coolant hoses.

Disconnect coolant hoses (1) with special tool 13 3 010 and release associated hose clamps.

Release bolt (2).

Detach auxiliary water pump (3) and disconnect associated plug connection.

Tightening torque.

Fig. 53: Detaching Auxiliary Water Pump

After installation:

- Fill and vent cooling system and check for leaks.