BMW X5: Leak-Testing Evaporator

Special tools required:

- 64 5 104

- 64 5 108

Necessary preliminary tasks:

- Remove expansion valve.

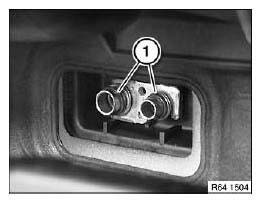

Replace sealing rings (1) and coat with refrigerant oil.

Fig. 90: Identifying Sealing Rings

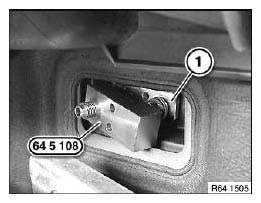

Mount special tool 64 5 108 and retainer (1) with screws of expansion valve.

Tightening torque.

Fig. 91: Identifying Special Tool (64 5 108)

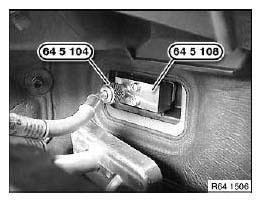

Connect special tool 64 5 104 to special tool 64 5 108.

Fig. 92: Identifying Special Tool (64 5 104 And 64 5 108)

IMPORTANT: Risk of damage: Use only nitrogen pressure bottles with pressure reducers for leak-testing.

Pressurize evaporator to 15 bar slowly only. Excessively fast pressurization and pressures in excess of 20 bar may cause damage to the evaporator.

Connect nitrogen pressure bottle with pressure reducer to pressure gauge and then connect to special tool 64 5 104 (connecting hose).

NOTE:

- Testing apparatus must be leakproof.

- Ambient temperature and temperature of vehicle must not change during the test procedure.

- Do not move the vehicle during this period.

Apply test pressure of 15 bar slowly and close nitrogen pressure bottle.

Check leak-tightness of testing apparatus and of connection to refrigerant line.

Set test pressure of 15 bar is only permitted to drop by 2 bar to 13 bar over a test period of 2 hours.

If the pressure loss is greater than 2 bar, this indicates that there is a leak in the evaporator unit.

After installation:

- Replace all sealing rings and moisten with refrigerant oil

- Evacuate and fill A/C system.