BMW X5: Adjusting Timing Of Camshaft(s) (N52K)

Special tools required:

- 00 9 120 TORQUE ANGLE MEASURING DIAL

- 00 9 250 TORSION ANGLE WRENCH WITH FLEXIBLE EXTENSION

- 11 0 300

- 11 4 280

- 11 4 281

- 11 4 282

- 11 4 283

- 11 4 290

- 11 9 340

Necessary preliminary tasks:

- Remove cylinder head cover

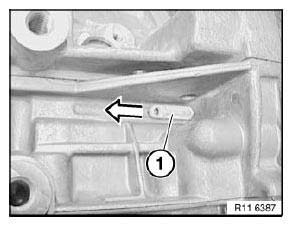

Remove fastener (1) in direction of arrow.

Installation:

Install fastener (1) with bore facing outwards.

Fig. 198: Fastener

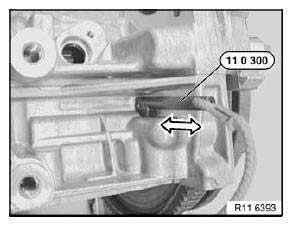

Rotate crankshaft at central bolt into TDC position.

Slide special tool 11 0 300 in direction of arrow into special tool bore and secure crankshaft.

IMPORTANT: On vehicles with optional extra SA205 (automatic transmission), there is a large bore for the TDC position shortly before the special tool bore. This bore can be confused with the special tool bore.

If the flywheel is secured in the correct special tool bore with special tool 11 0 300 , the engine can no longer be moved at the central bolt.

Fig. 199: Securing Crankshaft Using Special Tool (11 0 300)

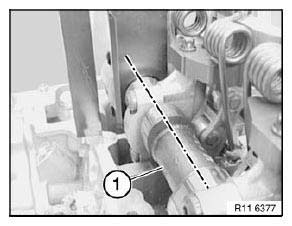

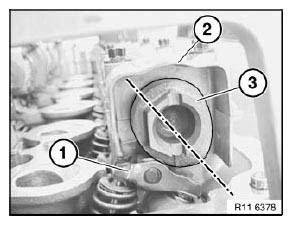

With 1st cylinder in firing TDC position, cams of inlet camshaft (1) at 1st cylinder point upwards at an angle.

Fig. 200: Inlet Camshaft

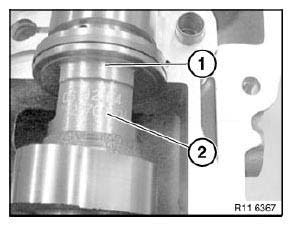

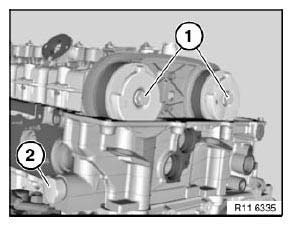

Part numbers (2) on inlet and exhaust camshafts (1) point upwards.

Fig. 201: Part Numbers On Inlet And Exhaust Camshafts

With 1st cylinder in firing TDC position, cams of exhaust camshaft (3) at 6th cylinder point downwards at an angle.

Cam follower (1) is not actuated.

NOTE: When the engine is installed, the position of the exhaust camshaft (3) for the timing can only be checked with a mirror.

Fig. 202: Exhaust Camshaft And Cam Follower

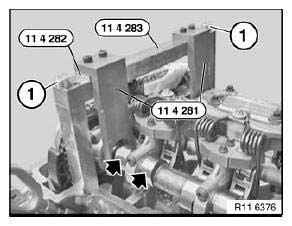

Secure special tool 11 4 283 to cylinder head with bolts (1).

NOTE: Fit special tool 11 4 282 underneath on side of inlet camshaft.

Mount special tool 11 4 281 on inlet and exhaust camshafts.

Fig. 203: Cylinder Head Bolts And Special Tools (11 4 282) And (11 4 281)

Release central bolts (1).

Release central bolts (1) with special tool 11 4 280 only.

Release chain tensioner (2) (have a cleaning cloth ready).

NOTE: Picture in CAD and does not show special tools.

Fig. 204: Central Bolts And Chain Tensioner

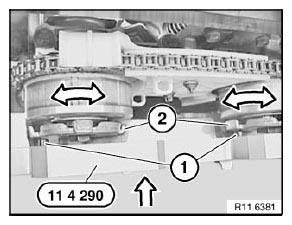

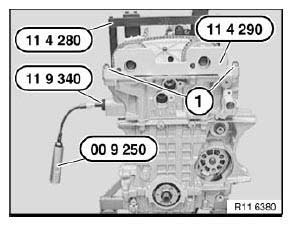

Turn sensor gears (2) in direction of arrow until locating pins (1) on special tool 11 4 290 match up.

Slide on special tool 11 4 290 in direction of arrow.

Fig. 205: Sensor Gears, Locating Pins And Special Tool (11 4 290)

Secure special tool 11 4 290 with bolts (1).

Screw special tool 11 9 340 into cylinder head.

Pretension timing chain with special tool 00 9 250 to 0.6 Nm.

Secure both central bolts of inlet and exhaust adjustment units with special tool 00 9 120 to inlet and exhaust camshafts.

Tightening torque: 11 36 1AZ.

Fig. 206: Special Tools (00 9 250), (11 9 340) And (11 4 290)

Assemble engine.