BMW X5: Sensor For Control Unit

REMOVING AND INSTALLING/REPLACING DIFFERENTIAL PRESSURE SENSOR (N52 / N52K / N51)

Necessary preliminary tasks:

- E90 / E91 / E92 / E93 / E87:

Remove lower section of microfilter housing. - E85 / E86 E90 / E91 / E92 / E93:

Remove left tension strut on suspension strut dome - E70:

Remove intake filter housing

IMPORTANT: Read and comply with notes on protection against electrostatic damage (ESD protection).

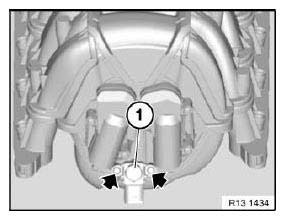

Release screws.

Unlock plug (1) and remove.

Pull differential pressure sensor (1) out of intake air manifold.

Fig. 5: Identifying Differential Pressure Sensor

Installation:

Read out fault memory of control unit of Digital Engine Electronics (DME).

Check stored fault messages.

Now clear the fault memory.

REPLACING COOLANT TEMPERATURE SENSOR (N52K)

WARNING: Danger of scalding! Only perform these tasks on an engine that has cooled down.

Recycling

Catch and dispose of escaping coolant.

Observe country-specific waste-disposal regulations.

Necessary preliminary tasks:

- Read out fault memory of DME control unit; if necessary, work through test schedules

- Switch off ignition

Lever out expansion rivets (1).

Press lock (2) and raise intake duct (3).

Detach intake duct (3) from air filter housing and remove.

Unclip Bowden cable for engine bonnet/hood actuator from transverse reinforcement (1).

Release screws on left and right sides. Tightening torque 51 71 4AZ.

Remove cross-brace (1).

Coolant temperature sensor is mounted on cylinder head at front.

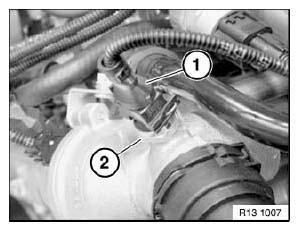

Unlock plug (1) and remove.

Release temperature sensor (2).

Installation:

Tightening torque 13 62 2AZ.

If necessary, top up coolant.

Check cooling system for leaks.

Fig. 6: Identifying Plug And Temperature Sensor

NOTE: Now clear the fault memory.

REMOVING AND INSTALLING/REPLACING AIR-MASS FLOW SENSOR (N52 / N52K / N53)

Necessary preliminary tasks:

- Read out fault memory of DME control unit; if necessary, work through test schedules

- Switch off ignition

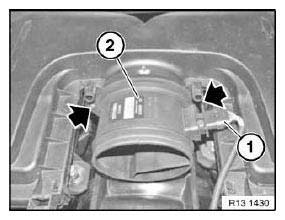

Release bolts.

Unlock plug (1) and remove.

Pull air-mass flow sensor (2) out of upper section of intake filter housing.

NOTE: Check stored fault messages.

Now clear the fault memory.

Fig. 7: Identifying Plug And Air-Mass Flow Sensor

NOTE: Check stored fault messages.

Now clear the fault memory.

Start Valves

REPLACING ALL FUEL INJECTORS

This work step is described.