BMW X5: Head-Up Display

REMOVING AND INSTALLING/REPLACING TRIM FOR HEAD-UP DISPLAY

Special tools required:

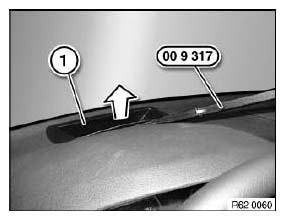

- 00 9 317.

Lever out trim for head-up display (1) with special tool 00 9 317 towards top.

Fig. 2: Removing Lever

Installation:

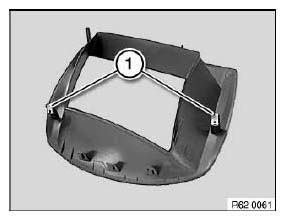

Make sure detent lugs (1) are correctly seated.

Fig. 3: Identifying Detent Lugs

REMOVING AND INSTALLING/REPLACING HEAD - UP DISPLAY

IMPORTANT: Read and comply with notes on protection against electrostatic damage (ESD protection).

IMPORTANT: Comply with notes and instructions on handling optical waveguides.

Necessary preliminary tasks:

- Remove instrument panel trim.

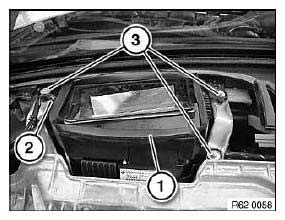

Remove foam seal (1) from head-up display.

Disconnect plug connection (2).

Release screws (3).

Tightening torque 62 30 2AZ. Carefully feed out head-up display towards top.

Installation:

- Clean head-up display lens.

Fig. 4: Identifying Plug Connection And Seal

Replacement:

Carry out programming/coding.

ADJUSTING HEAD-UP DISPLAY

Connect vehicle to BMW diagnosis system.

Select service function under following path:

- Service function

- Body

- Display and information functions

- Head-up display

- Adjusting head-up display

NOTE: The geometric representation of the head-up display can be adjusted with the service function.