BMW X5: Distribution Box, Power

REPLACING DISTRIBUTION BOX (LUGGAGE COMPARTMENT)

WARNING: Observe safety instructions for handling vehicle battery.

Necessary preliminary tasks:

- Disconnect battery negative lead.

- Remove flap in luggage compartment panel on right.

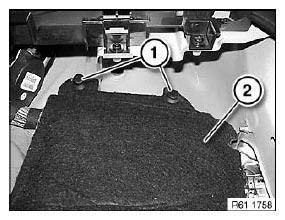

Release expansion rivet (1).

Remove insulating mat (2).

Fig. 143: Identifying Expansion Rivet And Insulating Mat

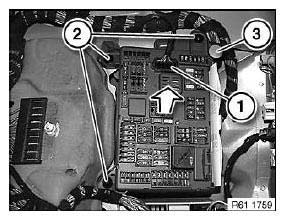

Disconnect plug connection (1).

Release bolts (2).

Disengage distribution box in direction of arrow.

Disengage emergency actuator (3).

Fig. 144: Disengaging Distribution Box

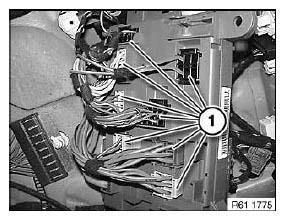

Disconnect plug connection (1).

Fig. 145: Identifying Plug Connection

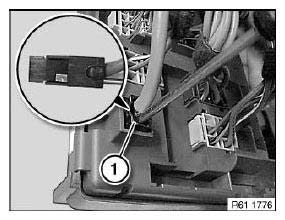

Disconnect plug connection (1).

Remove distribution box.

Fig. 146: Identifying Plug Connection

Replacement:

Remove fuses and relays.

REMOVING AND INSTALLING/REPLACING DISTRIBUTION BOX (ON BATTERY)

WARNING: Observe safety instructions for handling vehicle battery.

Notes and instructions on Intelligent Battery Sensor IBS.

Necessary preliminary tasks:

- Disconnect negative battery cable.

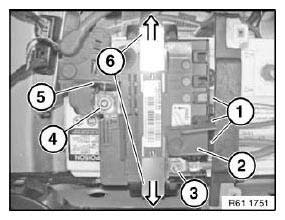

Disconnect plug connection (1).

Fold up covers (2).

Release nut (3) and remove cable shoe.

Tightening torque.

Fold up covers (5).

Unscrew nuts (4).

Tightening torque.

Using a screwdriver, expand locking bracket (6) at lower end and clip out.

Remove distribution box (2) towards top.

Fig. 147: Expanding Locking Bracket