BMW X5: Removing And Installing Automatic Transmission (GA6HP26Z) N62TU

Special tools required:

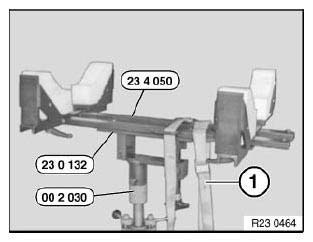

- 00 2 030

- 23 0 132

- 23 4 050

- 24 1 110

- 24 2 390

- 24 4 160

- 23 4 161

- 24 4 165

IMPORTANT: After completion of work, check transmission oil level.

Use only the approved transmission fluid.

Failure to comply with this requirement will result in serious damage to the automatic transmission!

WARNING: Danger to life! Mount securing fixture for vehicle on lifting platform to prevent the vehicle from slipping off or tilting down.

Necessary preliminary tasks:

- Disconnect battery.

- If necessary, remove fan cowl.

- Remove underbody protection.

- Remove reinforcement plate.

Important notes on installation are described in this work step.

- Remove exhaust system.

- Remove heat shields

- Remove propeller shaft from front differential.

- Remove propeller shaft

- Support engine with lifter when removing transmission

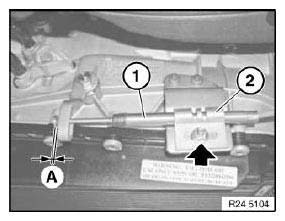

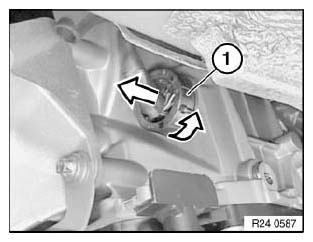

Unfasten nut.

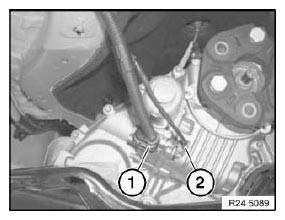

Disconnect cable (1).

Installation:

- Unfasten nut.

- Adjust cable by means of holder (2) until spacing A = 1 mm is obtained

- Tighten nut.

Fig. 6: Identifying Cable And Holder

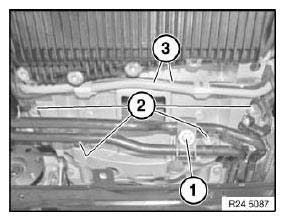

Unfasten screws (1 and 2).

Tightening torque. Release lines (3) from retaining clips.

Fig. 7: Identifying Screws, Lines And Retaining Clips

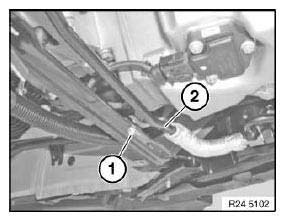

Release screw (1).

Detach oil line (2) from front axle.

Fig. 8: Identifying Screw And Oil Line

Release screw (1).

Disconnect hydraulic lines (2) to transmission fluid cooler.

Installation:

Replace sealing rings.

Fig. 9: Identifying Screw And Hydraulic Lines

- Unlock plug (1) by turning and disconnect

- Release cable from retainers

- Insert special tool 24 2 390 in sealing sleeve

These tasks are described in NOTES ON MECHATRONICS.

(Important: Observe important note)

Fig. 10: Identifying Plug

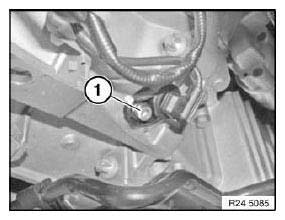

Release screw (1) and remove crankshaft sensor.

Fig. 11: Identifying Screw And Crankshaft Sensor

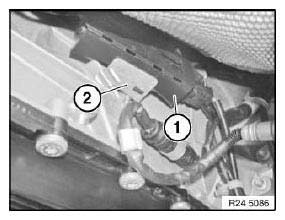

Release cable box (1) from holder (2).

Fig. 12: Identifying Cable Box And Holder

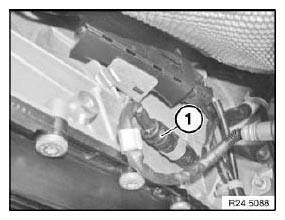

Release connector (1) from holder and disconnect.

Fig. 13: Identifying Connector And Holder

Supporting transmission:

Support with special tools 23 4 050, 23 0 132 and 00 2 030.

Secure transmission with tensioning strap (1).

Tasks are described in TRANSMISSION BRACKET.

Fig. 14: Identifying Tensioning Strap And Special Tools (23 4 050, 23 0 132,

00 2 030)

Unlock and detach plugs (1) and (2).

Fig. 15: Identifying Plugs

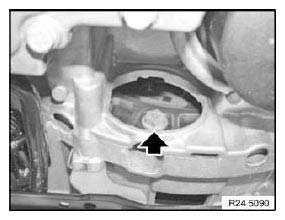

Crank engine at vibration damper in direction of rotation until screw is visible in opening.

Release all screws of torque converter with special tool 24 1 110.

Crank engine further and release remaining 3 bolts.

Tightening torque.

Fig. 16: Identifying Screws

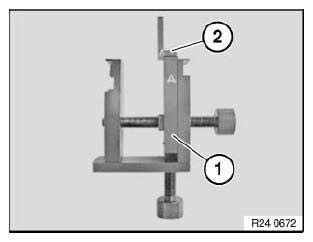

Prepare special tool (1) 24 4 161 (A) with shaped section (2) 24 4 165 side (A) to (A).

Fig. 17: Identifying Special Tool (24 4 161)

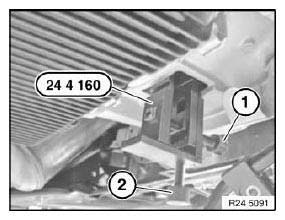

Insert special tool 24 4 160 into opening of transmission housing and tensions slightly with screw (1).

Raise by turning screw (2) and clamp down.

Then tighten down screw (1).

Fig. 18: Identifying Special Tool (24 4 160)

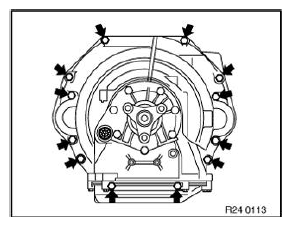

Release screws.

Tightening torque. Unflange transmission.

Fig. 19: Locating Screws

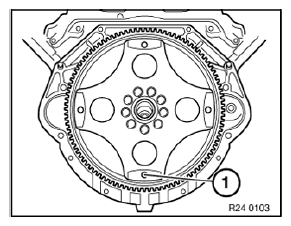

Installation:

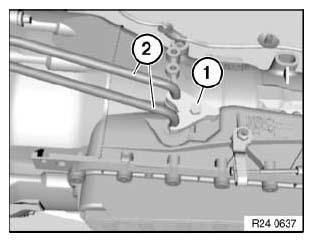

Bore (1) in driving disk must be accessible from opening on engine oil pan.

Fig. 20: Identifying Bore

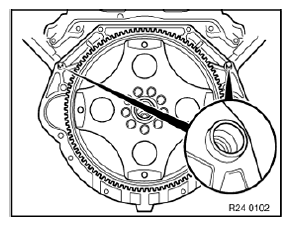

Check that dowel sleeves are correctly seated.

Replace damaged dowel sleeves.

Fig. 21: Identifying Dowel Sleeves

Installation:

Rotate torque converter until bore in torque converter is flush with bore in driving disk.

Flange automatic transmission to engine.