BMW X5: Extension Housing, Bea

REPLACING OUTPUT FLANGE SHAFT SEAL (GA6HP26Z)

Special tools required:

IMPORTANT: After completion of work, check transmission fluid level.

Use only the approved transmission fluid.

Failure to comply with this requirement will result in serious damage

to the

automatic transmission!

Necessary preliminary tasks:

- Remove rear underbody protection.

- Remove exhaust system.

- Remove heat shields.

- Support transmission.

- Remove transfer box.

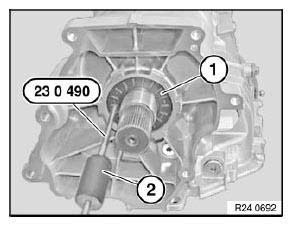

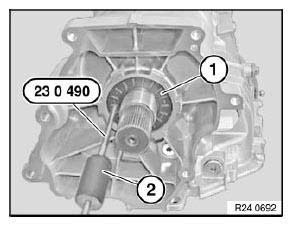

Drive a hole into radial shaft seal (1) using a center punch.

IMPORTANT: Do not use a drill as drillings may result in transmission

malfunction.

Screw special tool 23 0 490 into radial shaft seal (1).

Drive out radial shaft seal (1) with impact weight (2).

Fig. 33: Identifying Radial Shaft Seal With Special Tool (23 0 490)

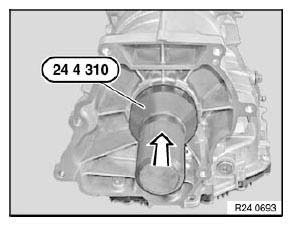

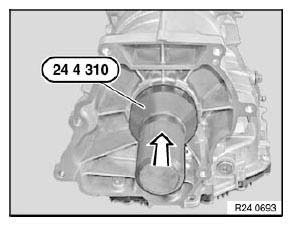

Installation:

Coat sealing lips of new radial seal with clean transmission oil.

Drive shaft seal firmly home with special tool 24 4 310.

Fig. 34: Identifying Special Tool (24 4 310)

READ NEXT:

REPLACING SELECTOR SHAFT SEAL (GA6HP26Z)

Special tools required:

24 5 361

24 5 362

24 5 364

24 5 366

IMPORTANT: After completion of work, check transmission fluid level.

Use only the approved t

REPLACING TORQUE CONVERTER SHAFT SEAL (GA6HP26Z)

Special tools required:

00 1 450

24 0 200

24 2 351

24 2 352

24 2 353

24 2 360

Necessary preliminary tasks:

Remove automatic transmission.

IM

MANUAL EMERGENCY RELEASE OF TRANSMISSION LOCK

In the event of a power supply interruption, e.g. flat battery or electrical

fault, the transmission lock must be

manually released, otherwise the wheel

SEE MORE:

Safety information

Warning

If the upper retaining strap is incorrectly used

for the child restraint system, the protective effect

is reduced. There is a risk of injury. Make

sure that the upper retaining strap does not run

over sharp edges and is not twisted as it

passes the upper anchor.

Warning

If

WARNING: Follow instructions for handling light bulbs (exterior

lights).

Rear light in side panel:

Remove flap in luggage compartment trim panel.

Turn socket housing and pull out of rear light.

NOTE:

Bulb, adaptive brake light

Bulb, reversing light

Bulb, brake light

Bulb, turn indicator light